Worldspace

Haptic robotic arm for excavator operation.

Overview

Worldspace is a haptic robotic arm interface designed to mimic the kinematics and proportions of an excavator. It was used as the primary hardware platform in a research study investigating The Effects of Haptic Feedback and Guidance in the Learning and Operation of Excavators. The project studies how haptic feedback influences learning efficiency, control precision, and physical exertion when operating excavators through a robotic arm interface. I contributed across human-subject experimentation, mechanical design, and real-time kinematics visualization, supporting both the research and system development aspects of the project.

Research & Experimental Setup

We conducted controlled user studies comparing excavator operation across four experimental conditions to isolate the effects of both interface type and haptic feedback.

The four experimental groups were:

- Joystick control with haptic feedback

- Joystick control without haptic feedback

- Worldspace robotic arm with haptic feedback

- Worldspace robotic arm without haptic feedback

My contributions included:

- Recruiting and assisting participants during experiments

- Running and supervising 36+ hours of training simulations

- Setting up Unity-based excavation tasks and logging performance data

Results showed a ~50% reduction in operator force exertion when haptic feedback was enabled, particularly when using the Worldspace interface, indicating improved ergonomics and control efficiency.

Mechanical Design & Safety Improvements

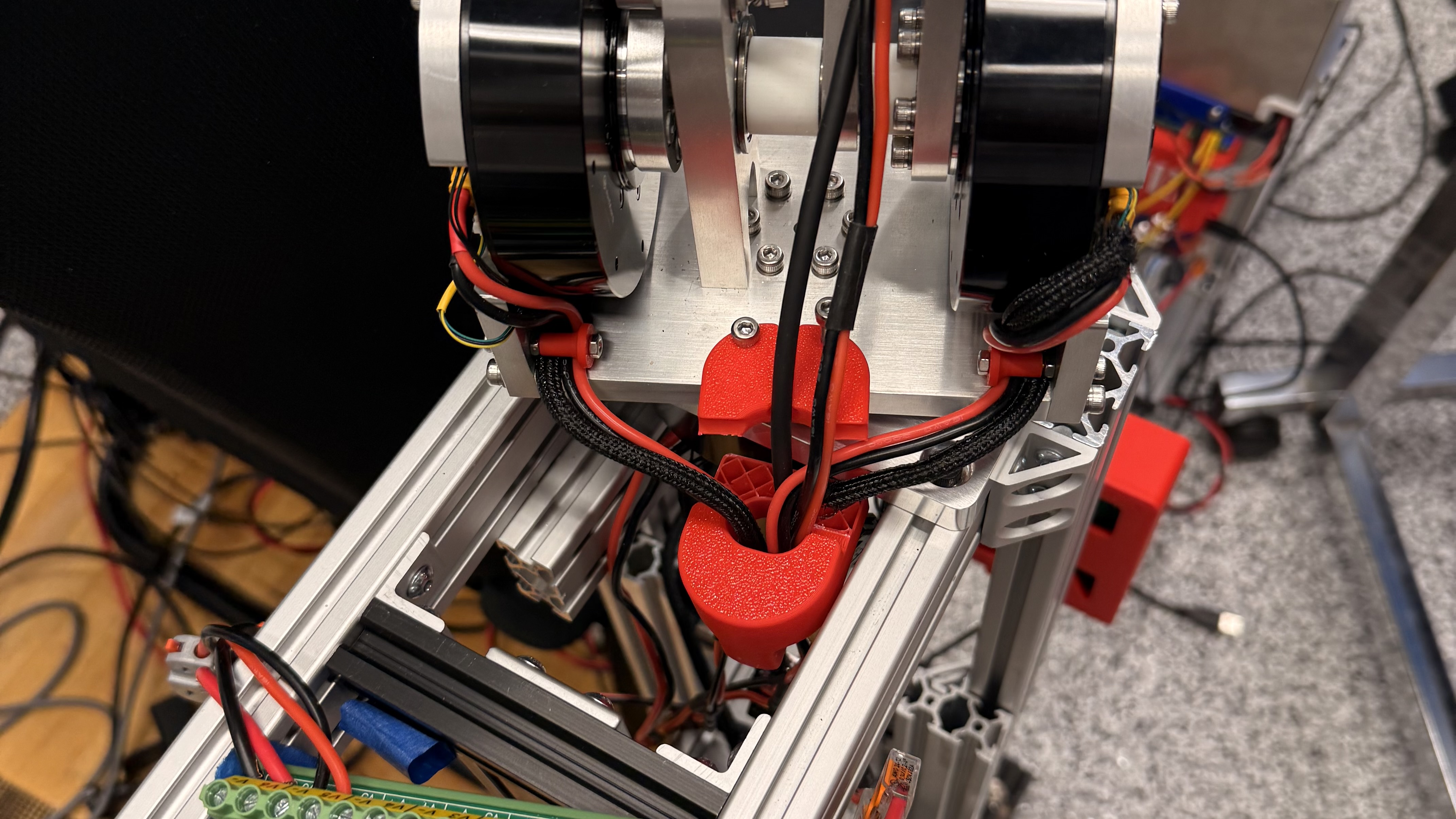

Wire Organizer Redesign

One major mechanical contribution was redesigning a wire organizer that also functioned as a mechanical stop for the robotic arm.

The original design:

- Frequently broke under stress

- Required unplugging and rethreading all wires to replace

I designed a new slot-based wire organizer that:

- Allowed wires to be routed without disconnecting

- Greatly reduced replacement time

- Improved durability and maintainability

This resulted in a 75%+ reduction in maintenance time.

Original wire organizer that frequently failed under mechanical stress

Original wire organizer that frequently failed under mechanical stress

Redesigned slot-based wire organizer enabling faster maintenance and improved durability

Redesigned slot-based wire organizer enabling faster maintenance and improved durability

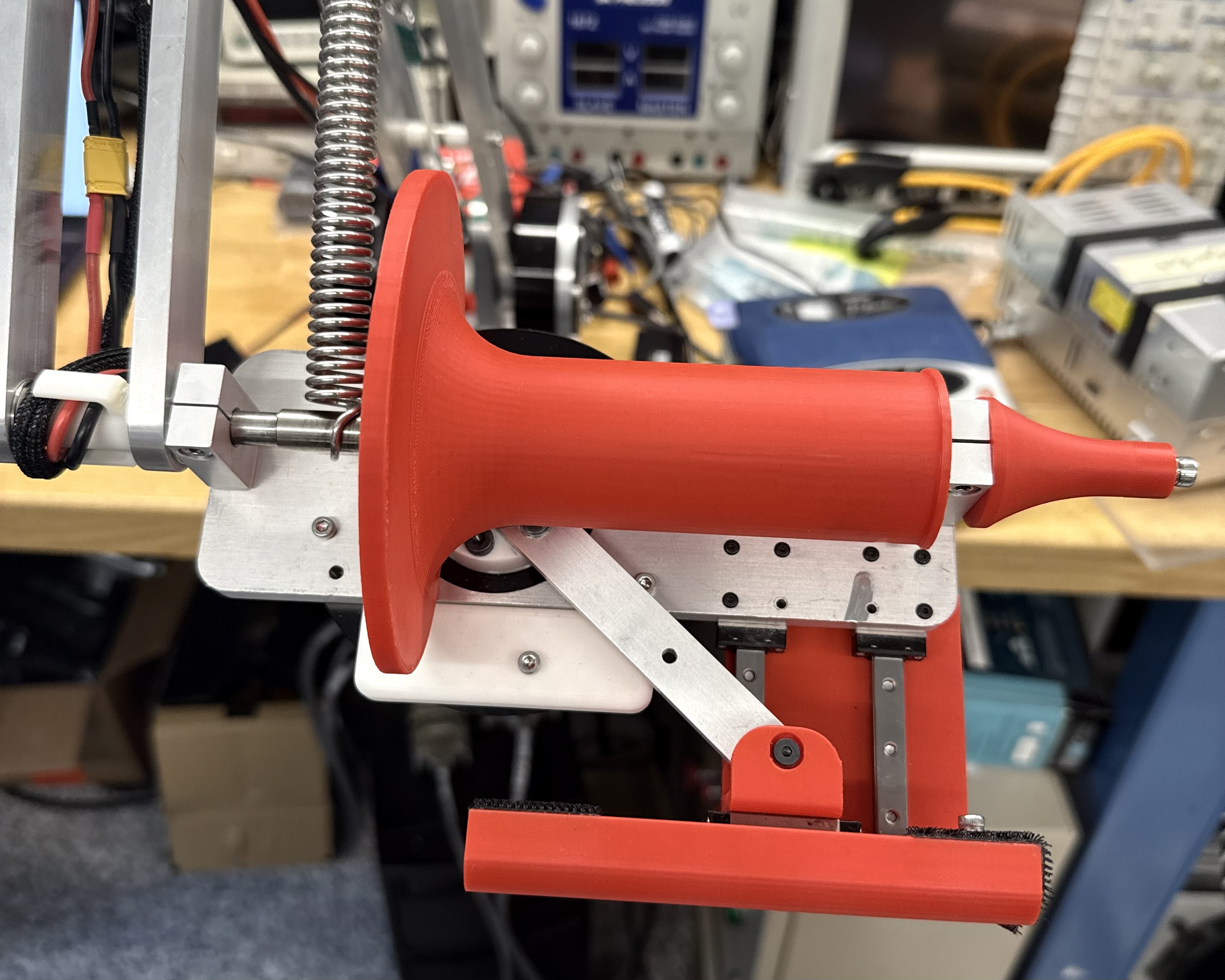

Gripper Safety Structure

Another safety-focused improvement addressed a finger injury risk in the gripper mechanism.

Originally:

- An exposed gap posed a risk of finger injury during operation

I designed a fan-like protective structure that:

- Expands and contracts with the gripper

- Protects 3 out of 4 fingers during operation

- Significantly improves user safety compared to the original design

Exposed gap in the original gripper design presenting a finger injury risk

Exposed gap in the original gripper design presenting a finger injury risk

Fan-like safety structure during gripper operation

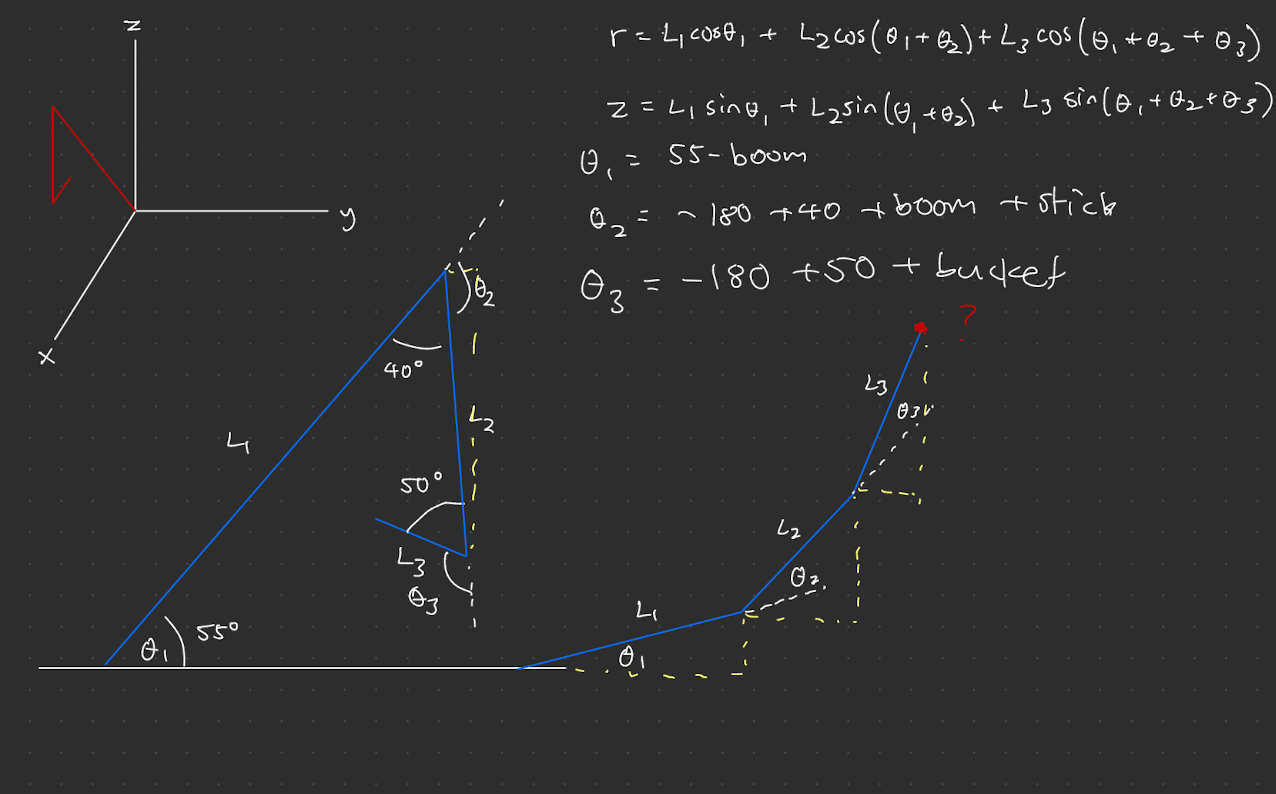

Kinematics & Real-Time Visualization

I implemented real-time forward kinematics for the 4-DOF robotic arm to track joint positions and the excavator bucket tip in 3D space.

This work involved:

- Computing 3D forward kinematics for each joint

- Mapping bucket tip position for environment interaction

- Enabling physics-based simulation such as soil dragging with haptic feedback

Technologies used:

- Python + Matplotlib for real-time visualization

- C++ and Unity for interactive simulation

Forward kinematics equations used to compute joint positions and excavator bucket tip location

Forward kinematics equations used to compute joint positions and excavator bucket tip location

Real-time forward kinematics visualization in Matplotlib

Real-time forward kinematics visualization in Unity