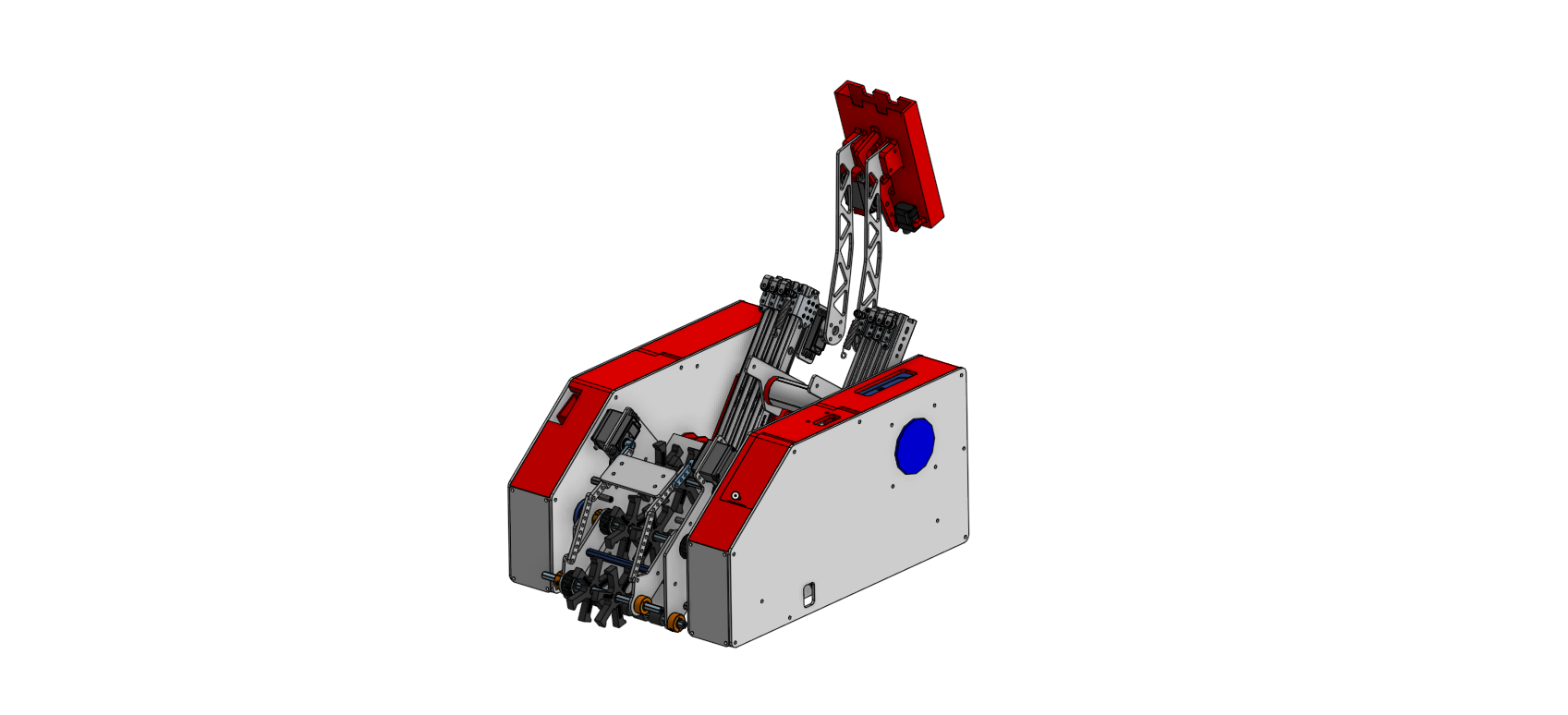

Scorpion 2.0

Competition robot for FIRST Tech Challenge CENTERSTAGE (2023-2024).

Overview

I served as team captain for my FTC team during the 2023–2024 CENTERSTAGE season. The game objective focused on collecting small plastic hexagonal pieces called pixels and stacking them onto a slanted scoring board, followed by an endgame hang. As in the previous season, I was heavily involved in designing, building, and programming the robot, contributing across mechanical design, system integration, and autonomous software.

Game Constraints & Design Goals

CENTERSTAGE introduced several unique constraints that strongly influenced the robot design:

- The robot needed to stack pixels progressively higher on a slanted board

- An endgame hang required lifting the entire robot off the ground

- A central field bridge limited robot height to 14 inches

- The robot needed sufficient reach while remaining compact

Our goal was to design a robot that balanced low profile, high reach, and mechanical strength without sacrificing mobility.

Mechanical Design & Build

Drivetrain

We again chose a mecanum drive base to enable omnidirectional movement and precise alignment with the scoring board.

- Four motors, each connected via belt drive

- Compact footprint to fit under the 14-inch bridge

- Designed for stability while supporting tall extensions

Lift, Intake, and Endgame

To meet the combined stacking and hanging requirements, the robot used:

- Three motors powering the linear slides to maximize lifting force

- A roller-based intake driven by a single motor

- A pixel storage box capable of holding two pixels at once

- An arm and linear slide system that could deposit:

- One pixel at a time

- Both pixels simultaneously

The high-powered linear slide system allowed the robot to reliably lift itself during the endgame hang.

Software & Automation

Localization & Control

The robot used a localization setup similar to the previous season:

- Three odometry pods

- An IMU for heading correction

Position control was handled using three independent PID loops, controlling:

- (x) position

- (y) position

- Heading (θ)

This resulted in a navigation system with sub–1 inch positional error under competition conditions.

Waypoint-Based Navigation

Autonomous routines were implemented using:

- Waypoint-based navigation

- Inflated waypoints to maintain clearance

- Interpolated paths for smooth motion

This framework allowed the robot to navigate along arbitrary paths and reliably execute complex autonomous sequences.

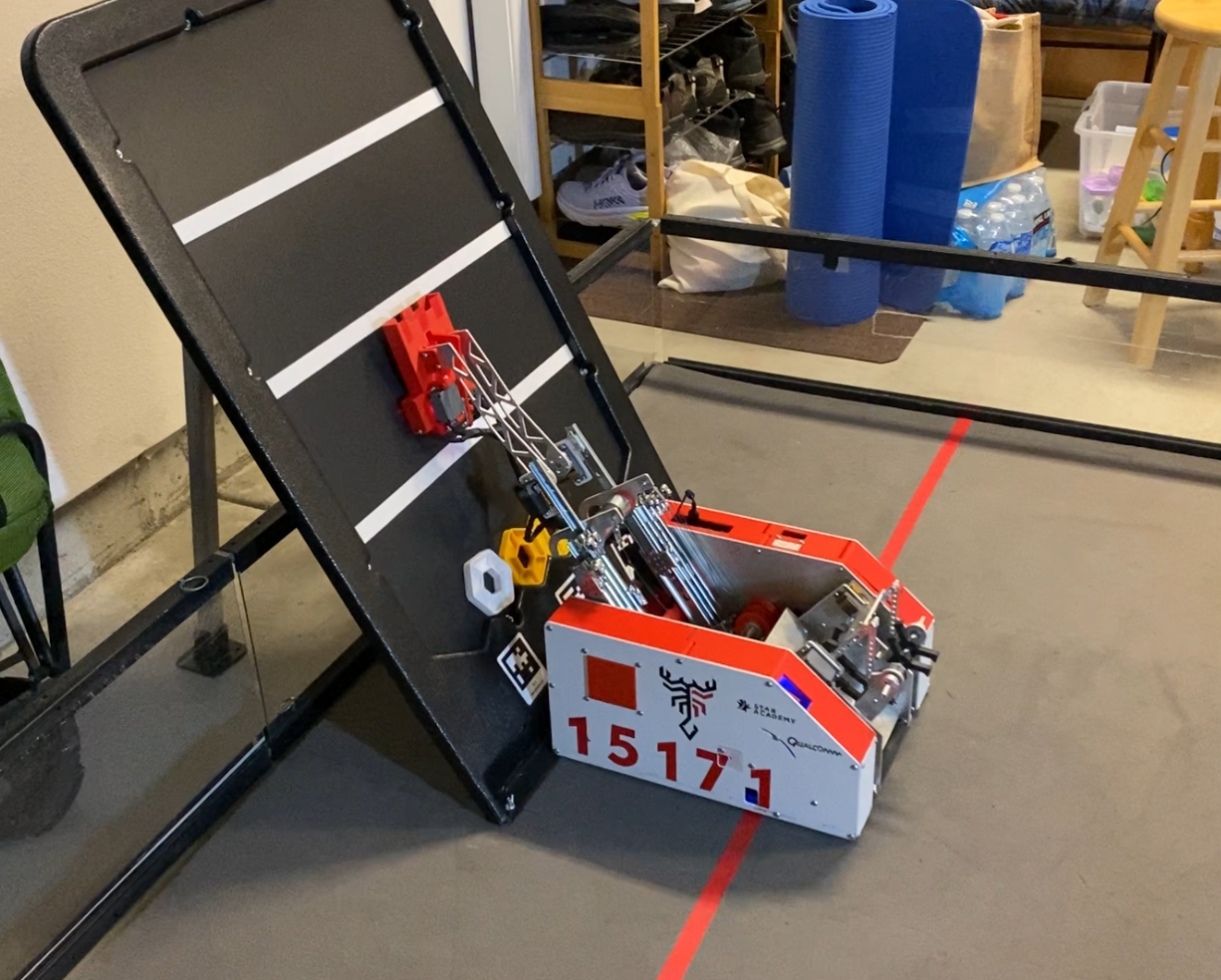

Full autonomous routine stacking pixels on the board

Endgame Performance

Endgame hang using the linear slide system

The reinforced lift system provided enough torque and stability to lift the robot consistently at the end of matches.