Scorpion

Competition robot for the FIRST Tech Challenge POWERPLAY (2022–2023).

Overview

The POWERPLAY game focused on stacking cones onto poles, rewarding precision, speed, and reliable autonomous behavior. Our objective was to build a robot that could score consistently in autonomous while remaining agile and controllable during tele-op. As team captain, I was heavily involved in both the mechanical design and software development of the robot, contributing the majority of the CAD and programming while coordinating overall system integration.

My Role

- Team Captain

- Primary contributor to:

- Robot CAD

- Autonomous and control software

- Drivetrain redesign and optimization

- Involved in mechanical iteration, sensor integration, and autonomous strategy design

Mechanical Design & Build

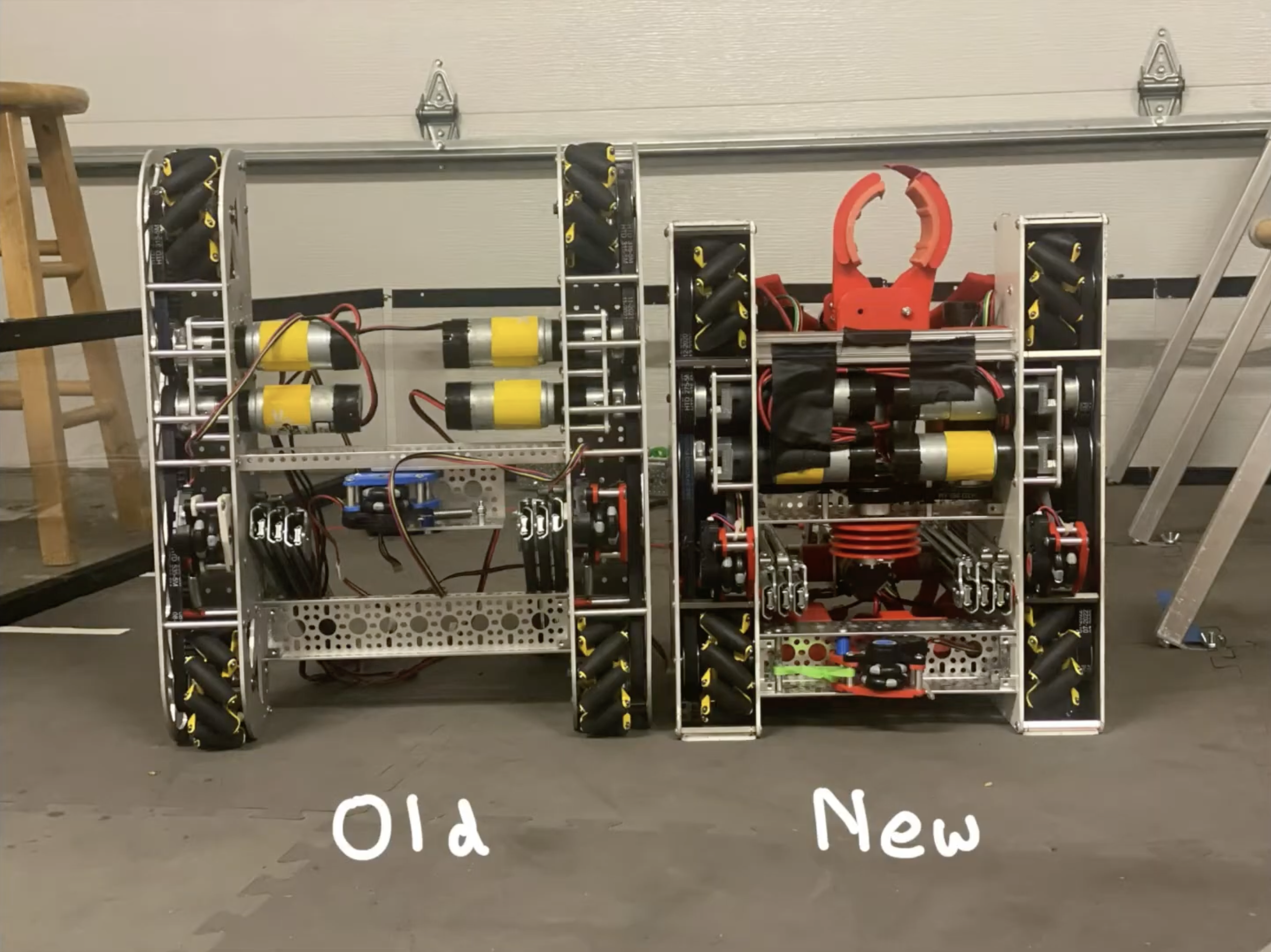

Drivetrain

The robot used a mecanum drive base to enable omnidirectional movement, which was essential for maneuvering around poles and other robots. Each wheel was driven by an individual motor via belt drive, prioritizing compactness and reliability.

One of my main mechanical contributions was a drivetrain redesign:

- Reduced the drivetrain footprint by 2 inches in both length and width

- Improved turning radius and field mobility

- Enabled tighter alignment around scoring poles

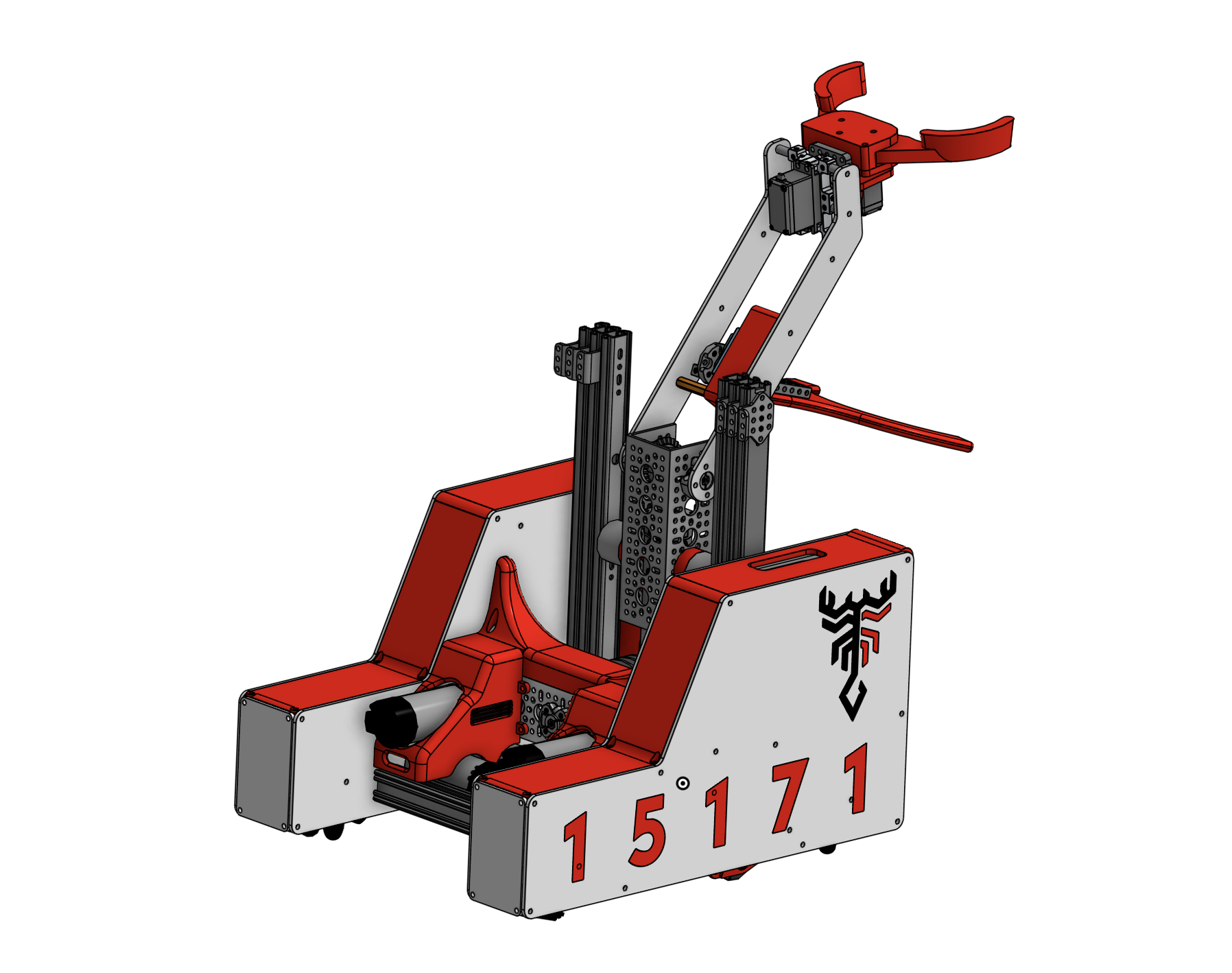

Full robot CAD model (Onshape)

Full robot CAD model (Onshape)

Comparison between original and redesigned drivetrain

Comparison between original and redesigned drivetrain

Cone Manipulation System

The cone manipulation system consisted of:

- A linear slide lift for vertical extension

- A pivoting arm

- A rotatable claw for controlled cone intake and placement

The robot was fully CADed in Onshape and built using:

- GoBilda components

- CNC-machined aluminum plates

- Custom 3D-printed parts

This hybrid approach enabled rapid iteration while maintaining structural rigidity where needed.

Software & Autonomous System

Localization

Autonomous performance was built on a robust localization system using sensor fusion from:

- Three odometry pods, providing real-time (x, y, θ)

- An IMU, used primarily for more accurate heading (θ) estimation

While the odometry pods alone could estimate pose, the IMU significantly improved heading stability over long autonomous runs.

Waypoint-Based Navigation

Using the localization system, I implemented a waypoint navigation framework:

- Autonomous paths defined as sequences of target (x, y, θ) poses

- Interpolation between waypoints to generate smooth motion

- Reusable, field-agnostic autonomous routines

This abstraction allowed rapid iteration on autonomous strategies without modifying low-level control logic.

Autonomous run demonstrating waypoint navigation and scoring

State Management & Sensor Feedback

Autonomous behavior was organized using a finite state machine (FSM):

- States handled navigation, intake, lift positioning, and scoring

- A distance sensor mounted on the claw detected whether a cone was within reach

- Sensor feedback triggered state transitions (e.g., intake → lift)

This improved reliability during real match conditions where alignment was imperfect.

Distance sensor detecting a cone and triggering claw intake

Results & Performance

- Placed 1st in San Diego at the regional level

- Placed 2nd in California at the state level

- Ranked 18th worldwide in overall robot performance

- Demonstrated consistent autonomous navigation and scoring across competitions

- Maintained reliable cone detection and intake under match conditions

- Improved field mobility after drivetrain redesign